rockwell hardness test blocks steel|hrc hrb hra difference : importers Buehler's industry leading hardness testing blocks ensure accuracy, integrity, and traceability in hardness testing processes. The comprehensive range of scales and blocks, associated with . Isis Valverde estreou na TV como a Ana do Véu, na novela ".

{plog:ftitle_list}

Resultado da 24 de fev. de 2024 · This web page is for subscribers of Buckeye Sports Bulletin, a newspaper that covers Ohio State sports news and events. To .

An economical way to determine the hardness of steel on the Rockwell C-scale. Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.Wilson Rockwell hardness test blocks set the standard for the industry and are made from the highest quality material to insure the most uniform and repeatable Rockwell test blocks available.

Newage® test blocks for Rockwell scales are ideal for verifying your Rockwell hardness testing system. Rockwell test blocks serve as a reference, with each block having an average .Rockwell Regular Test Blocks, Rockwell Superficial Test Blocks, Brindell Hardness Test Blocks. Made to order to your specific hardness range.Buehler's industry leading hardness testing blocks ensure accuracy, integrity, and traceability in hardness testing processes. The comprehensive range of scales and blocks, associated with .Rockwell Test Blocks – Superficial Scale. Gilmore Rockwell Hardness Test Blocks (also known as Rockwell Test Coupons) are manufactured and calibrated to current ASTM E-18 .

NextGen hardness test blocks are all certified in accordance with ASTM E384 (Vickers and Knoop), E18 (Rockwell) or E10 (Brinell). All the blocks are calibrated and accredited to ISO guide 25 and are performed in an ISO 17025 compliant .

Highest quality steel, brass and aluminum. Rockwell test block surface hand lapped and diamond polished to a mirror finish. Superior accuracy and ease of testing for the operator. Special heat treat process insures .

We supply hardness reference blocks that cover both Rockwell and Superficial Rockwell hardness, with blocks for all scales that cover the range of hardness values. All reference blocks are delivered with a UKAS calibration certificate.We offer indenters for all your hardness testing needs, including: “Rockwell,” Brinell, Vickers, Knoop, LEEB and specialty indenters. Discover reliable hardness standard test blocks from .ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application.

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should .Rockwell test blocks are pieces of steel, brass, or aluminum that have been specially heat treated and calibrated for consistency. By using a test block, Rockwell hardness testers can be calibrated for optimal precision. All of .

Choose from our selection of Rockwell hardness testing file sets, small spot Rockwell hardness testers, Rockwell hardness testing files, and more. . It is an economical way to determine the hardness of steel on the Rockwell C-scale. . These testers come with indenters for different scales, three anvils, four test blocks, and a case to store .

5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficialHardness Test Blocks & Accessories. Phase II offers a vast array of different hardness test blocks for Rockwell, Brinell and Vickers scales, as well as Portable hardness testers

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .The Rockwell hardness test continues to be applied as a tool for assessing . HRC measurement value for steel test blocks at three hardness levels. ... 82 Figure C.1 Test block surface illustrating the locations (letters A through K) of certified hardness values .

In 1986 the company manufactured its first Rockwell Hardness Test Block. Now the company ships Rockwell, Brinell, Vickers, Knoop and LD blocks all over the world. In early 2000 DLECI was NVLAP accredited and still is. . The most common test in the USA is the Rockwell HRC for hard steel and HRBW for soft alloys. Thin metals are tested with .Our hardness reference blocks cover the full spectrum of hardness test methods, scales and values and are used in a number of different industries around the world, including aerospace, automotive, science, engineering, manufacturing, medicine and primary metal production. . Rockwell & superficial hardness reference blocks. Rockwell and .

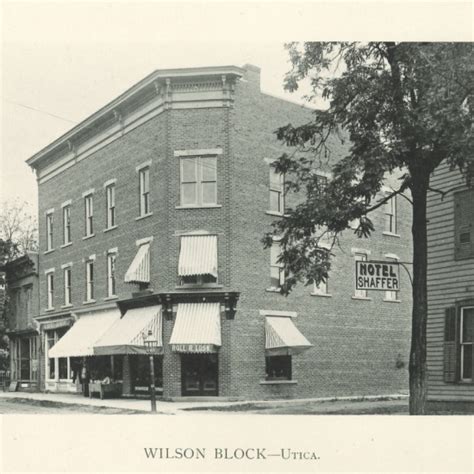

wilson block

hardness tests - the Rockwell test is a measure of the resistance of material, specifically metals, to permanent indentation. Indentation hardness is not a fundamental . Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the diameter of the indentation only 0.019 inch, which is Some of the most common materials used for hardness test blocks include: Steel: Steel is a common material for hardness test blocks and is often used for Rockwell hardness testing. The blocks can be made from a range of different steel alloys, such as SAE 4130, which has a known hardness value and is used as a standard reference material. .ROCKWELL HARDNESS TESTING MACHINES . 1/16" Carbide Ball Indenter Hardness test Block 60 HRC Hardness test Block 60 HRC . For steel hardenability testing Small V-anvil 810-042 (Outside ø10 mm) For round specimens (max. ø16 mm) VARI-REST 810-027 For testing long specimens (commonly usedSuntec's Rockwell hardness standards test blocks are essential for precise calibration of your hardness testers. Trust our high-quality blocks for accurate and consistent hardness measurements in your testing process. . Rockwell Superficial Hardness Standards Test Blocks Select options This product has multiple variants. The options may be .

Hardness Test Block, Rockwell Hardness Test Blocks , Leeb Hardness Test Blocks, Portable hardness test blocks, Vickers hardness test blocks . Rockwell Hardness Test Blocks (Steel): Part No. Description Shape Range .International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in .Check your hardness tester for accuracy against a block with a known hardness rating. Each block is tested according to ASTM E10, which checks the hardness at five locations along the block. They include a certificate that lists the block’s actual hardness, as well as each of the five measurements taken during the test. Blocks also include a .The connection between hardness and carbon content is clearly visible in the example below: the higher the carbon content, the higher also the HRC of various types of White Steel: White Steel 1 / 63 HRC / C = 1.25-1.35 % White Steel 2 / 61-62 HRC / C = 1.05-1.15 % White Steel 3 / 60 HRC / C = 0.80-0.90 % Measuring hardness There are several .

Steel Hardness Conversion Table. This table shows approximate hardness of steel using Brinell, Rockwell B and C and Vickers scales. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. The right hand column show an approximate equivalent tensile strength.4.3 Verification of the indenter 4.3.1 Diamond cone indenter (scales A, C, D, N) To verify the reliable performance of the conical indenter in conformance with this part of ISO 6508, a direct With the increasing use of materials other than common steel and brass, as well as requirements to test thin materials and sheet steel, a basic knowledge of the factors that must be considered in choosing the correct scale to ensure an accurate Rockwell test in necessary. The choice is not only between the regular hardness test and superficial .

what can car be tested on impact in experiments

Rockwell Hardness Tester Model No. 3814 Operation Manual . 3-test blocks, 120 diamond indenter, 1/16 ball indenter are provided. Unpacking Loose Parts Storage Box: . Four Test Blocks E. 120 Diamond Indenter F. 1/16" Steel Ball indenter Remove 4-nuts from side panels of crate. Carefully lift crate up from base. Leave the tester bolted to .Please contact us here: 1- 888-400-4243 (USA & Canada) 1-631-321-0160 (International) WESTport Corporation 510 Montauk Highway West Islip, NY 11795In this revision the requirement of method for Rockwell superficial hardness test, calibration of standardized blocks and verification of Rockwell hardness testing machines have been included. In the preparation of this standard, assistance has been drawn from ASTM E 18 -97a ‘Standard test methods for Rockwell hardness and Rockwell

The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell hardness test on metals. The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of the indentation as the force on the . CIMETRIX offers the CMX1000 Portable Hardness Rockwell Tester Machine for measuring metal hardness in Rockwell C, Rockwell B, Vickers, Brinell and Shore scales. . Measurable Material:Steel and cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, aluminum casting (see Metals tab above) . Calibration test block .

what can impact blood test results

Keep your eyes peeled for the Sheriff’s Star in Lone Star Jackpots™, for if it appears enough times on the reels, it could land you a . Ver mais

rockwell hardness test blocks steel|hrc hrb hra difference